The global cold chain is in the midst of a significant transformation, and at the heart of this shift is the rising prominence of Commercial Refrigeration equipment China. As a major manufacturing hub and an increasingly sophisticated consumer market, China has become a key driver of innovation and supply in commercial refrigeration. For business owners, facility managers, and project developers who utilize a comprehensive, one-stop approach to HVAC (Heating, Ventilation, and Air Conditioning) systems, understanding the benefits of leveraging Chinese-manufactured commercial refrigeration equipment is absolutely critical. This equipment is no longer simply about keeping things cold; it is now an integral component of a total climate control and energy management ecosystem.

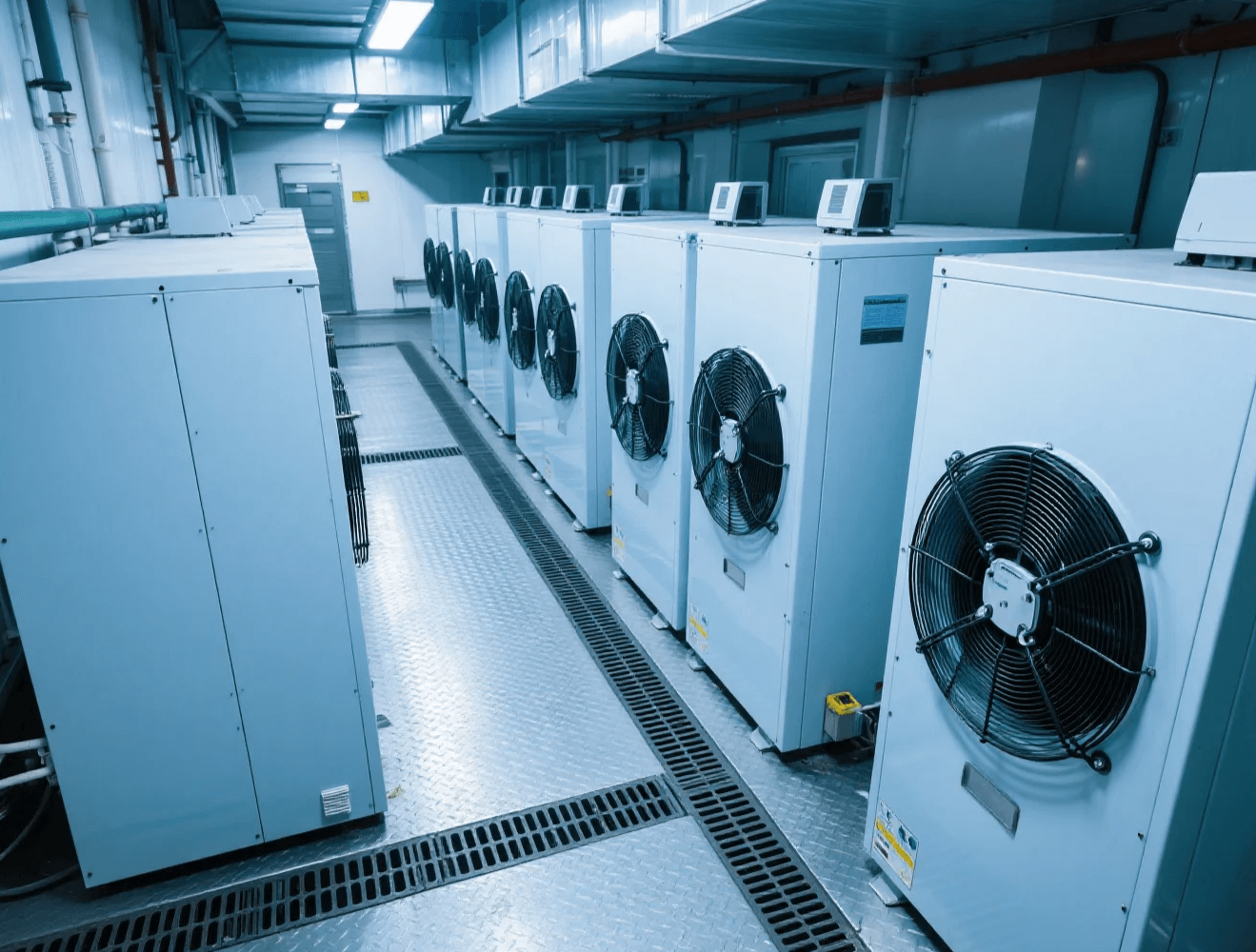

The sheer scale of the Chinese market, which is experiencing rapid expansion fueled by the growth of food retail, hospitality, and pharmaceutical sectors, necessitates robust and reliable cooling solutions. Consequently, manufacturers have invested heavily in R&D to meet stringent global standards for energy efficiency and environmental compliance. The key advantage for the one-stop HVAC product user is the seamless integration this equipment offers, ensuring optimal performance across all climate-related functions, from air conditioning to critical temperature maintenance in display cases and cold rooms.

Historically, refrigeration and HVAC systems were often treated as separate, distinct entities within a commercial building or facility. However, in modern business operations, particularly those dealing with perishable goods or sensitive materials, a disconnected approach leads to inefficiencies, higher operating costs, and increased risk of equipment failure. This is where the one-stop HVAC solution, anchored by high-quality Commercial Refrigeration equipment China, provides immense value.

A consolidated system approach ensures that commercial refrigeration units and general HVAC components—like chillers, air handling units, and ventilation systems—are designed to work in harmony. For instance, the waste heat generated by a refrigerator’s condensing unit can be recovered and repurposed to assist in a building’s heating or hot water supply. Commercial Refrigeration equipment China is increasingly engineered to support this kind of heat recovery, translating directly into tangible energy savings. Furthermore, consolidated procurement and installation drastically simplify project management, reducing the complexity and potential for errors that arise when sourcing from multiple vendors. This streamlined process is highly favored by project developers looking for quick, reliable deployment.

The Chinese market is quickly adopting intelligent, IoT-enabled refrigeration systems. These systems offer real-time temperature monitoring, predictive maintenance alerts, and remote diagnostics, a feature that is extremely beneficial for international clients managing facilities remotely. Integrating these smart features into a centralized HVAC control platform allows facility managers to monitor an entire building’s climate performance from a single dashboard. This level of granular control ensures that food safety standards are met consistently while energy consumption is optimized automatically. Therefore, the adoption of modern Commercial Refrigeration equipment China with these advanced features is fundamentally about risk mitigation and operational excellence.

The reputation of Commercial Refrigeration equipment China has evolved significantly, moving past an emphasis on low cost to a focus on advanced technology, durability, and environmental responsibility. The products now entering the global market are characterized by several distinct advantages that are attractive to sophisticated buyers.

Energy consumption is one of the most significant operating expenses for any business utilizing commercial cooling. China's manufacturers are at the forefront of adopting and implementing energy-saving technologies. For example, the use of variable speed compressors and advanced insulation materials in refrigerated display cases is now standard practice. The widespread adoption of energy-efficient solutions directly addresses the global imperative to reduce carbon footprints and operating expenses, providing a dual benefit for businesses.

In line with global environmental protocols, there has been a definitive shift toward natural refrigerants with low Global Warming Potential (GWP), such as CO2 (R-744) and hydrocarbons (R-290). Approximately 40% of new commercial refrigeration units manufactured in China are now utilizing these eco-friendly refrigerants. For buyers, choosing modern Commercial Refrigeration equipment China means future-proofing operations against tightening international regulations and demonstrating a commitment to corporate social responsibility. This shift is crucial for companies operating under various governmental environmental compliance mandates.

Recognizing the diverse needs of the food retail, cold logistics, and pharmaceutical sectors, Chinese manufacturers offer a high degree of customization. Whether a business requires walk-in coolers, specialized pharmaceutical storage, or unique refrigerated display cabinets for a supermarket, flexible and modular systems are readily available. This ability to tailor solutions ensures that the refrigeration equipment seamlessly integrates into any facility’s one-stop HVAC design, optimizing both space and function.

The decision to source Commercial Refrigeration equipment China as part of a single, integrated HVAC solution yields significant operational and financial benefits for the end-user.

Simplified Maintenance and Servicing: When all components—refrigeration, heating, and cooling—come from compatible or single-source suppliers, maintenance procedures become unified. Technicians require training on fewer distinct systems, which dramatically improves the speed and quality of service. Routine checks, for example, often involve assessing both HVAC and refrigeration coil health simultaneously, preventing small issues from escalating into expensive, total system failures.

Reduced Total Cost of Ownership (TCO): Although the initial investment in advanced, integrated equipment may seem higher, the long-term TCO is significantly lowered. This reduction is achieved through lower energy bills, decreased downtime due to preventative maintenance, and an extended equipment lifespan. The robust and reliable nature of modern Commercial Refrigeration equipment China plays a pivotal role in this equation.

Compliance Assurance: For international operators, navigating complex safety and energy regulations can be challenging. Working with manufacturers who specialize in one-stop solutions often means that the entire system—including the refrigeration component—is pre-certified to meet major international standards (e.g., CE, UL, RoHS), ensuring that compliance is maintained effortlessly from the point of installation.

The landscape of commercial climate control is evolving rapidly, moving toward highly integrated and intelligent solutions. Commercial Refrigeration equipment China is not just keeping pace with this evolution; it is helping to set the standard. For any entity focused on one-stop HVAC products—seeking high efficiency, reliability, and simplified management—leveraging the advanced, environmentally-conscious, and customizable solutions originating from China is a forward-thinking investment. By choosing an integrated approach, businesses are positioning themselves for operational excellence, significant long-term cost savings, and a strong commitment to sustainable practices.

A: One-stop sourcing ensures that your commercial refrigeration units are perfectly matched and integrated with your building's heating and ventilation systems. This synergy allows for advanced control over temperature and humidity across your entire facility, maximizes energy recovery (e.g., using waste heat), and simplifies maintenance, as all components operate under a single, unified control platform.

A: Yes. Leading manufacturers in China are actively transitioning to low-GWP natural refrigerants like R290 (Propane) and R744 (CO2) and are designing equipment to meet or exceed international energy efficiency ratings. When selecting a vendor, always confirm relevant certifications (e.g., CE, UL) and their refrigerant technology.

A: Smart technology allows for critical features such as remote, real-time temperature monitoring, which is vital for food safety and pharmaceutical cold chains. It also enables predictive maintenance—alerting technicians to potential issues before they cause system failure—significantly reducing costly downtime and extending the equipment’s useful life.

Subscribe for the latest news and insights

We respect your privacy

Connect on social media