The modern commercial and industrial landscape demands HVAC (Heating, Ventilation, and Air Conditioning) systems that are not only robust and reliable but also supremely energy-efficient. In this context, VAV system manufacturer China has emerged as a critical global player, driving innovation in Variable Air Volume (VAV) technology. These manufacturers are no longer just component suppliers; they are architects of integrated, one-stop HVAC solutions. This detailed guide explores the profound role and distinct advantages of partnering with a Chinese VAV system manufacturer, focusing on the seamless integration of their products into comprehensive building management systems. Choosing the right partner means securing a future of optimized comfort, reduced operational costs, and sustainable building performance.

VAV systems represent a significant technological advancement over traditional Constant Air Volume (CAV) systems. The fundamental difference lies in how they manage airflow and temperature. While a CAV system maintains a constant airflow regardless of the thermal load, leading to energy waste, a VAV system dynamically adjusts the volume of conditioned air supplied to a space based on the real-time requirements. This adaptive control is not merely a feature; it's a fundamental shift towards demand-driven, energy-smart operation. This approach results in substantial savings, particularly during part-load conditions, which constitute the majority of a building's operating hours. The ability to precisely meter and deliver conditioned air exactly where and when it is needed is the core value proposition of VAV technology.

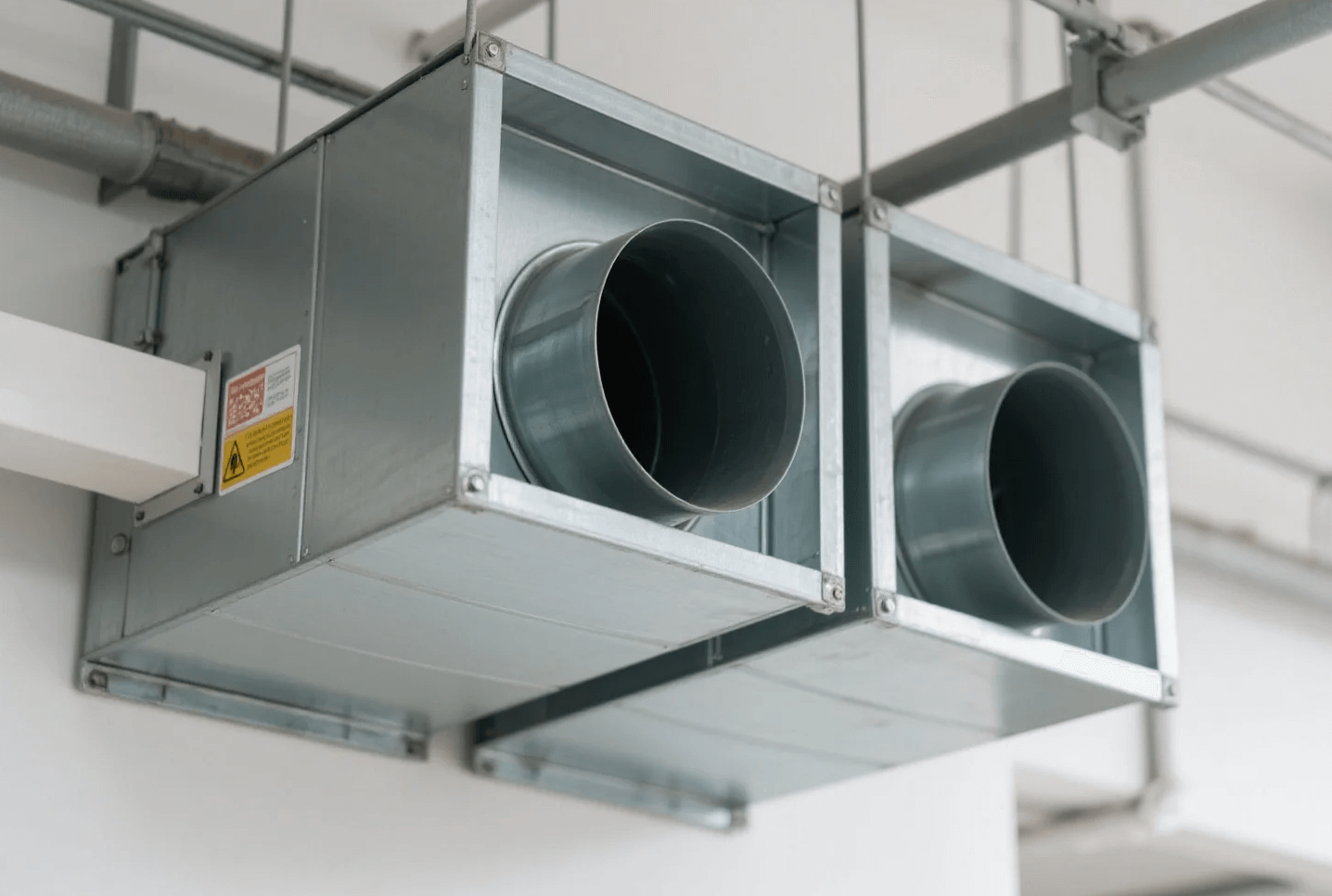

An integrated VAV system is a complex ecosystem, not a single device. It typically comprises VAV boxes (terminal units), variable frequency drives (VFDs) on the supply and return fans, sophisticated DDC (Direct Digital Control) controllers, and a network of sensors. The VAV box, often considered the heart of the system, modulates airflow into the zone. The synergy between these components ensures precise temperature control and minimizes fan energy consumption, which often accounts for a substantial portion of a building's total energy use. When these components are sourced from a single, specialized VAV system manufacturer China, the integration process is inherently smoother, reducing commissioning time and minimizing potential communication glitches between hardware.

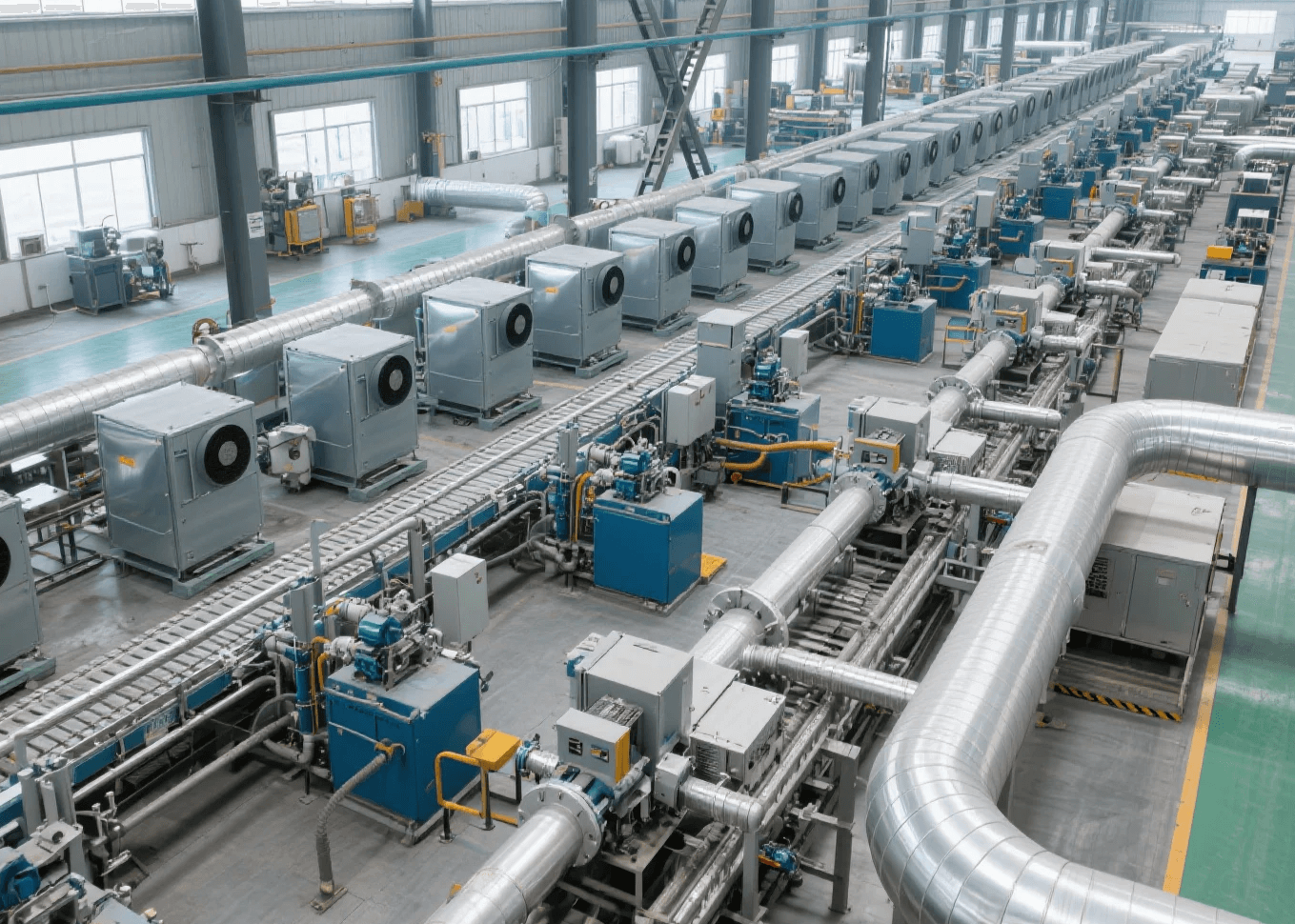

One of the undeniable advantages of engaging with a VAV system manufacturer China is the benefit derived from massive production scale and optimized supply chains. Through extensive automation and vertically integrated manufacturing processes, these companies achieve economies of scale that translate directly into competitive pricing without compromising quality. Furthermore, the capacity for large-volume production means they can reliably meet the demanding timelines of global commercial construction projects. The efficiency gained from this industrialized approach ensures that high-quality VAV products are accessible for projects of all sizes, from boutique commercial centers to sprawling industrial complexes.

Contrary to outdated perceptions, Chinese manufacturers are at the forefront of HVAC technology R&D. Leading VAV system manufacturers in China invest heavily in developing next-generation products, including ultra-low-leakage terminal units and advanced controllers capable of BACnet or Modbus communication protocols. This technological push is essential for integrating with complex Building Automation Systems (BAS), ensuring their products are future-proofed against evolving industry standards. This forward-looking commitment means that the products are not just manufactured to spec but often help set the new standards for efficiency and connectivity in the global HVAC market.

The ultimate value proposition offered by a premier VAV system manufacturer China is the comprehensive one-stop solution. Users no longer need to source VAV boxes from one supplier, air handlers from another, and controls from a third. A single manufacturer can now provide the entire gamut: air handling units (AHUs), fan coil units (FCUs), VAV terminals, chillers, heat pumps, and the necessary control infrastructure. This simplification reduces project complexity, minimizes compatibility issues, and streamlines logistics and warranty management for the end-user. This consolidated supply chain significantly lowers administrative overhead and accelerates project delivery schedules.

Modern VAV boxes manufactured in China utilize high-accuracy differential pressure sensors and digital actuators. These components allow for airflow measurement and control with an error margin often less than $pm 5%$. This precision is paramount in ensuring comfort and indoor air quality (IAQ), especially in critical environments like laboratories or hospitals. The trend is moving towards pressure-independent VAV boxes, which automatically compensate for duct pressure fluctuations, maintaining the desired airflow regardless of system variations. This digital accuracy ensures consistent thermal conditions across all zones, eliminating the 'hot and cold spots' often associated with less sophisticated systems.

A crucial feature for today's smart buildings is seamless integration. The VAV controllers produced by a prominent VAV system manufacturer China are designed to communicate effortlessly with central BAS platforms. Through open protocols, data on temperature, airflow, damper position, and occupant status can be shared in real-time. This connectivity facilitates predictive maintenance schedules, allows for advanced fault detection, and enables building managers to implement holistic energy conservation strategies across multiple zones. The ability to integrate VAV systems into cloud-based energy management systems allows for continuous, data-driven optimization.

In commercial office spaces and hospitality environments, noise control is as important as temperature control. Manufacturers are heavily focused on acoustic engineering, designing VAV boxes with internal sound attenuators and utilizing low-noise fan designs (for Fan-Powered VAV terminals). This attention to detail ensures that the system provides optimal thermal comfort without introducing distracting noise, thereby enhancing occupant well-being and productivity. Achieving low noise criteria (NC) ratings is a non-negotiable standard for top-tier VAV products destined for high-end applications.

As part of the one-stop solution, many Chinese manufacturers now offer integrated Energy Recovery Ventilator (ERV) units. These systems work synergistically with the VAV network to precondition incoming fresh air using the energy from the exhausted indoor air. This significantly reduces the load on the main VAV air handling unit, resulting in substantial operational energy savings and meeting increasingly stringent green building standards. This comprehensive approach underscores the commitment to sustainable HVAC solutions, helping clients achieve certifications like LEED and WELL.

In high-rise commercial offices, the solar load and occupancy levels fluctuate dramatically throughout the day. VAV systems excel here because they allow for granular control of each zone or office. For instance, a perimeter office receiving morning sun can receive less cool air than a core office with higher internal heat gains. This ability to match supply to demand minimizes temperature swings and ensures tenant satisfaction, a key metric for property managers. The flexibility of VAV design allows for easy re-zoning if the building layout changes, protecting the owner's long-term investment.

While VAV might seem counter-intuitive in applications requiring strict air change rates (like hospitals or laboratories), specialized VAV technology is indispensable. Fume hoods in laboratories require specific exhaust rates, and lab-grade VAV systems precisely control the supply air to maintain required room pressurization and safety levels. The reliability and accuracy provided by a leading VAV system manufacturer China are paramount in these life-critical applications. The DDC controls ensure fast response times to pressure changes, which is vital for maintaining sterile or contamination-free conditions.

For the end-user, the principal advantage is the reduced Total Cost of Ownership (TCO). While the initial capital cost might be slightly higher than simpler CAV systems, the long-term energy savings are profound. Studies consistently show VAV systems can reduce HVAC energy consumption by $30%$ to $60%$ compared to constant volume systems. When combined with the operational efficiency gained from a single-source one-stop supplier, the return on investment (ROI) is compelling. This long-term value is what drives adoption globally, positioning VAV technology as the economic and environmental standard.

Selecting the correct manufacturing partner requires due diligence beyond pricing. Prospective users should evaluate:

Certifications: Look for international standards like ISO 9001 (Quality Management) and certifications such as AHRI, ETL, or CE. These guarantee products meet global performance and safety benchmarks.

Technical Support: A robust manufacturer offers comprehensive pre-sales consultation and post-sales technical support, including BIM modeling and commissioning assistance.

Customization: The ability to customize terminal units (e.g., specific insulation, coating, or control sequences) for unique project requirements is a strong indicator of manufacturing flexibility and expertise.

Sustainability Focus: Manufacturers committed to producing products that use environmentally friendly refrigerants and minimize material waste demonstrate a forward-thinking, responsible philosophy.

In conclusion, the sophisticated and integrated solutions provided by a premier VAV system manufacturer China offer unparalleled value in the modern HVAC landscape. By choosing a partner focused on innovation, efficiency, and one-stop service, users can realize significant improvements in building performance and sustainability. This partnership ensures that your HVAC investment is future-proof, energy-efficient, and optimized for maximum occupant comfort.

The main benefit is energy efficiency. VAV systems adjust airflow based on demand, which drastically reduces the energy consumed by the fan motors compared to CAV systems, which run at a constant, high volume.

Yes. Leading VAV system manufacturers in China design their controllers to utilize globally recognized, open communication protocols like BACnet and Modbus, ensuring seamless compatibility with all major international BAS platforms.

A one-stop solution drastically simplifies project management, procurement, and logistics. It ensures all HVAC components (from chillers to VAV boxes) are engineered to work together perfectly, minimizing potential integration conflicts and streamlining warranty claims.

VAV systems are typically more cost-effective for larger buildings with multiple zones and fluctuating loads. However, smaller, high-quality VAV terminal units are increasingly being used in smaller commercial and specialized spaces where precise temperature or pressure control is critical.

Subscribe for the latest news and insights

We respect your privacy

Connect on social media