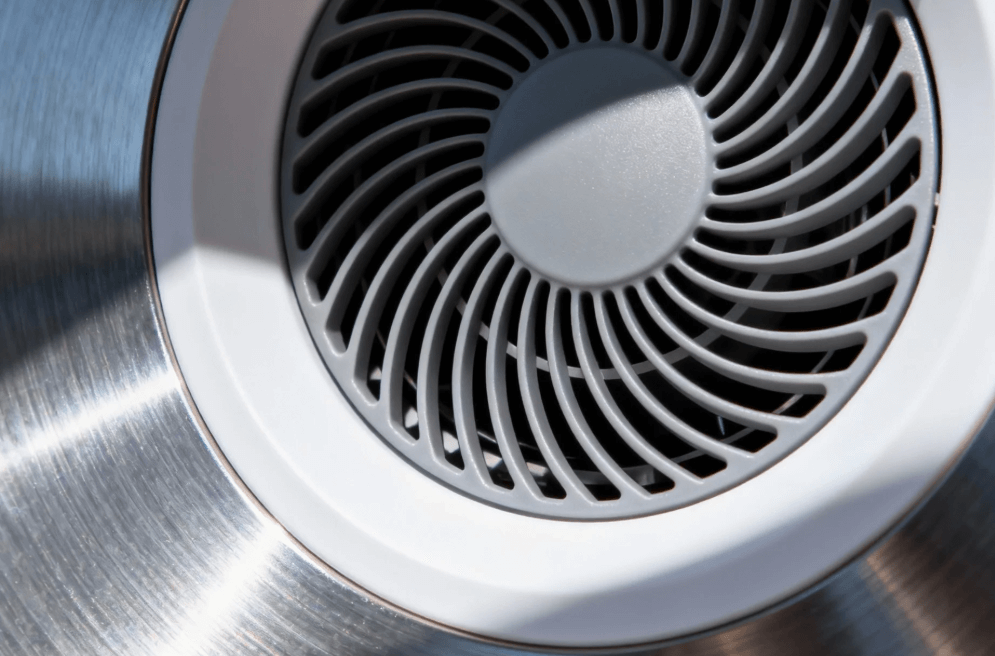

In the vast ecosystem of Heating, Ventilation, and Air Conditioning (HVAC) systems, the air diffuser stands as the final, crucial component responsible for introducing conditioned air into the occupied space. Central to high-performance HVAC product solutions is the Circular Swirl Air Diffuser, which utilizes a unique vane configuration to discharge air in a powerful, rotational motion. This action creates a high-induction swirl pattern that rapidly mixes the supply air with the room air, effectively eliminating temperature stratification and minimizing draft risk. For architects, HVAC engineers, and facility managers, the choice of the right diffuser is critical for operational efficiency and occupant well-being; the question is, how does the specialized fluid dynamics of the Circular Swirl Air Diffuser translate into superior thermal comfort and greater energy savings compared to conventional discharge methods? This comprehensive analysis will explore the core principles, advantages, and strategic value of the Circular Swirl Air Diffuser in modern building designs.

The exceptional performance of the Circular Swirl Air Diffuser is fundamentally rooted in the principles of fluid dynamics, particularly its ability to generate high induction and rapid decay.

The defining feature of the Circular Swirl Air Diffuser is its high induction ratio. Induction refers to the volume of room air that is drawn into the discharged air stream. By generating a powerful swirl, the diffuser creates a low-pressure core that aggressively pulls surrounding room air into the jet. This rapid mixing process is extremely efficient. The swift blend of supply air (which is typically much cooler or warmer than room temperature) with the ambient air causes the discharge air temperature to decay very quickly. This rapid decay is key because it means the air stream reaches the occupied zone at a temperature very close to the desired room temperature, preventing the sensation of cold drafts during cooling or localized hot spots during heating.

Due to the intense mixing achieved through high induction, the Circular Swirl Air Diffuser can successfully handle higher temperature differentials and higher air change rates than traditional ceiling diffusers. Despite these high air volumes, the overall air movement within the occupied space remains gentle because the momentum of the swirling jet dissipates quickly after mixing. This results in an optimized air distribution that minimizes air stratification (where hot air pools near the ceiling) and maintains comfortable, low air velocities across the occupants, a critical factor for achieving high user satisfaction in commercial environments like offices and retail spaces.

The design and installation flexibility of the Circular Swirl Air Diffuser allow it to be a versatile component across various building types and HVAC configurations.

The Circular Swirl Air Diffuser is engineered primarily for ceiling installation, often integrating seamlessly into modular ceiling grids. Its circular geometry and sometimes subtle face design ensure a clean, professional aesthetic that complements modern architectural styles. Manufacturers offer various models, including those designed for integration into plaster ceilings or exposed ductwork, allowing for maximum flexibility. The robust construction, often utilizing materials like steel or aluminum, ensures structural integrity and minimizes vibration, contributing to lower noise levels when paired with properly sized ductwork.

One significant technical advantage of the Circular Swirl Air Diffuser is its strong performance across both Constant Air Volume (CAV) and Variable Air Volume (VAV) systems. In VAV systems, the air flow rate can drop significantly during periods of low thermal load. Traditional diffusers often struggle to maintain an effective air pattern at low flow rates, leading to "dumping" (where cold air drops directly onto occupants). However, the inherent stability of the swirling discharge pattern ensures that the Circular Swirl Air Diffuser maintains its high induction and mixing characteristics even when the air volume is substantially reduced, guaranteeing consistent comfort and air quality regardless of the operational mode.

The specialized air distribution pattern makes the Circular Swirl Air Diffuser the preferred choice for specific, high-demand commercial and institutional settings.

In modern commercial office buildings, high ceilings and open-plan layouts are common. The effective throw and intense mixing power of the Circular Swirl Air Diffuser allow it to effectively condition these large, open areas, ensuring that the warm or cool air reaches the full height and depth of the occupied zone without creating uncomfortable drafts near the discharge point. Similarly, in spaces with very high ceilings, such as lobbies, auditoriums, or convention centers, the diffuser's high-momentum swirl jet can reach the floor level successfully, achieving uniform temperature distribution that would be impossible with standard radial or square pattern diffusers.

While the primary use is for comfort, the mixing efficiency of the Circular Swirl Air Diffuser also provides benefits in environments where controlled air movement is important, such as specific production areas or large laboratories. By quickly mixing the air and sweeping the conditioned air across the space, the diffuser helps dilute contaminants and maintain a consistent environment. This rapid air change capability is essential for managing indoor air quality (IAQ), showcasing the Circular Swirl Air Diffuser's role as a high-performance solution that goes beyond basic temperature control.

Q1: What is the main benefit of the swirl pattern produced by the Circular Swirl Air Diffuser?

A: The main benefit is high induction, meaning the supply air rapidly mixes with a large volume of room air, causing the temperature to decay quickly and preventing uncomfortable drafts in the occupied zone.

Q2: Can the Circular Swirl Air Diffuser be used in VAV (Variable Air Volume) systems?

A: Yes, it performs exceptionally well in VAV systems. The stable nature of the swirl pattern ensures that the diffuser maintains effective air mixing and low velocities even when the air flow rate is significantly reduced.

Q3: How does the diffuser contribute to energy efficiency?

A: By enabling the use of higher temperature differentials between the supply air and room air, the Circular Swirl Air Diffuser allows the chiller to operate more efficiently, resulting in lower energy consumption for the entire HVAC system.

Subscribe for the latest news and insights

We respect your privacy

Connect on social media