In the vast landscape of Heating, Ventilation, and Air Conditioning (HVAC), industrial and commercial cooling systems represent a significant portion of both initial capital investment and long-term operating costs. Selecting the correct central chiller technology is, therefore, a strategic decision that directly impacts energy consumption, maintenance overheads, and environmental compliance. Among the high-capacity options available, the Air Cooled Screw Chiller has emerged as a cornerstone solution, particularly valued for its high reliability, operational flexibility, and straightforward installation process. This technology utilizes a screw-type compressor to provide cooling, and rejects the heat directly into the ambient air, eliminating the need for a separate cooling tower and associated complex water management systems.

For facility managers and engineers overseeing comprehensive HVAC product integrations, understanding the nuances of this technology is paramount. The fundamental question guiding these professionals is: How does the advanced design and inherent efficiency of the Air Cooled Screw Chiller translate into superior performance and a clear advantage over other chiller types in a modern, integrated HVAC environment? This comprehensive analysis will explore the core mechanics, strategic installation benefits, and the specific applications where the Air Cooled Screw Chiller proves to be the most effective and sustainable choice.

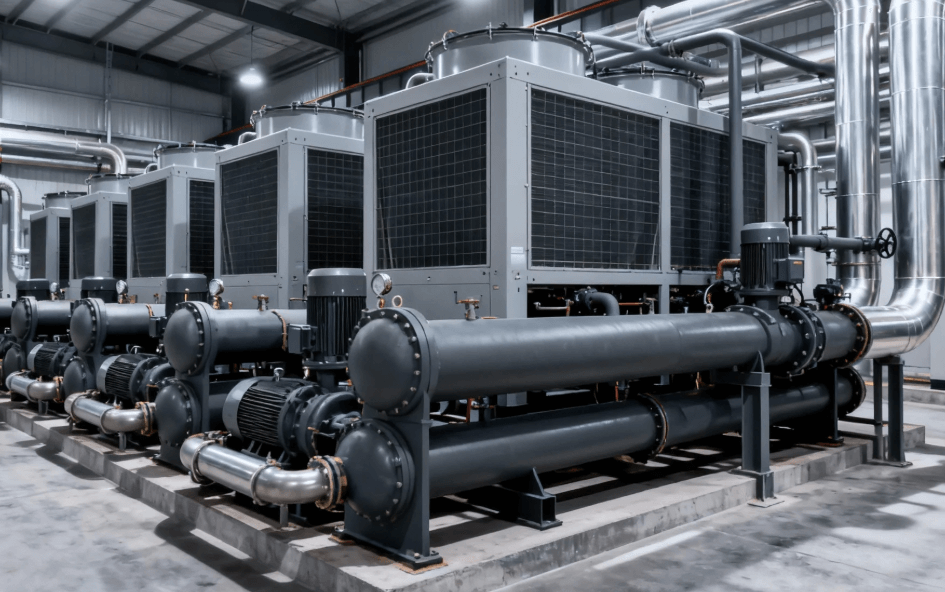

The efficiency and reliability of the Air Cooled Screw Chiller are rooted in the sophisticated design of its screw compressor and the direct air-based heat rejection mechanism.

At the heart of the Air Cooled Screw Chiller is the positive displacement screw compressor. This component utilizes two mating, helically-grooved rotors—a male rotor and a female rotor—that intermesh. As the rotors turn, they trap, compress, and discharge refrigerant vapor continuously. This mechanism offers several distinct advantages over traditional reciprocating or centrifugal compressors. Firstly, screw compressors handle large volumetric flow rates efficiently and reliably. Secondly, they possess excellent part-load efficiency due to their capacity control mechanism, typically a sliding valve, which allows them to adjust output smoothly to meet fluctuating cooling demands without significant energy penalties. This part-load performance is critical, as HVAC systems rarely operate at full capacity.

The "air cooled" designation is the defining feature of the Air Cooled Screw Chiller. Heat absorption occurs inside the evaporator, where chilled water is produced. This absorbed heat is then transferred to the refrigerant, which is compressed and sent to the air-cooled condenser. Here, a massive bank of fins and tubes, coupled with powerful condenser fans, rejects the heat directly into the outside air. The crucial benefit of this design is the elimination of all water-side infrastructure associated with heat rejection, including cooling towers, condenser water pumps, and water treatment systems. This dramatically simplifies installation, reduces ongoing water utility costs, and negates the need for anti-corrosion and anti-fouling chemical treatment, leading to lower overall maintenance requirements.

Beyond the mechanical design, the implementation of an Air Cooled Screw Chiller provides profound strategic advantages for facility management and system integration.

Since the Air Cooled Screw Chiller does not require a cooling tower or indoor machine room for heat rejection, manufacturers can design the unit for outdoor installation. This dramatically reduces the space requirements within the building footprint, freeing up valuable internal real estate for other uses. Furthermore, installation is significantly simplified. The chiller is delivered as a single packaged unit, requiring only connection to the chilled water pipes and the electrical power supply. This streamlined process facilitates rapid deployment in both new construction and retrofitting projects, making the Air Cooled Screw Chiller a preferred choice for projects with aggressive timelines.

The design robustness of the Air Cooled Screw Chiller makes it particularly resilient in geographically challenging environments. In regions facing water scarcity or high water costs, eliminating the cooling tower provides substantial operational savings and sustainability compliance. Additionally, in areas with harsh weather conditions, such as freezing temperatures, the system design avoids the need for complex freeze protection systems required for exposed cooling tower pipework. Many units also incorporate advanced controls that manage fan speed and staging, ensuring reliable operation across a wide range of ambient temperatures, from mild climates to extreme heat conditions.

The versatile performance profile of the Air Cooled Screw Chiller makes it suitable for a broad spectrum of HVAC and industrial applications, particularly those requiring medium to large cooling capacities.

For large commercial office buildings, hospitals, universities, and shopping centers, the Air Cooled Screw Chiller offers an ideal balance of capacity and maintainability. Its excellent part-load efficiency ensures energy savings throughout the year, as cooling loads fluctuate significantly between peak hours and off-peak periods. Furthermore, the simplified maintenance schedule, free from cooling tower maintenance complexity, translates directly into lower operational expenditure and more reliable year-round cooling for critical facilities like data centers housed within these buildings.

In manufacturing sectors that require controlled process temperatures—such as plastics molding, metal finishing, and food and beverage production—the Air Cooled Screw Chiller provides the stability and redundancy needed. Many industrial applications demand specific low water temperatures. Modern screw chillers are capable of achieving precise temperature control, and their modular design allows manufacturers to install multiple units, creating built-in redundancy that prevents total shutdown in the event of a single unit failure. This reliability is non-negotiable in time-sensitive manufacturing processes.

Q1: What is the primary operational saving associated with an Air Cooled Screw Chiller?

A: The primary saving comes from eliminating the need for a cooling tower and associated water treatment systems, which substantially reduces water consumption, sewage costs, and chemical maintenance expenditures.

Q2: How does the screw compressor contribute to efficiency at partial load?

A: The screw compressor uses a sliding valve capacity control mechanism that allows it to smoothly modulate its output to meet lower cooling demands. This prevents the energy spikes associated with cycling on and off, leading to excellent part-load efficiency.

Q3: Where should an Air Cooled Screw Chiller typically be installed?

A: Since it rejects heat directly into the air, the unit is almost always designed and specified for outdoor installation (e.g., on rooftops or at ground level), saving valuable indoor floor space.

Subscribe for the latest news and insights

We respect your privacy

Connect on social media