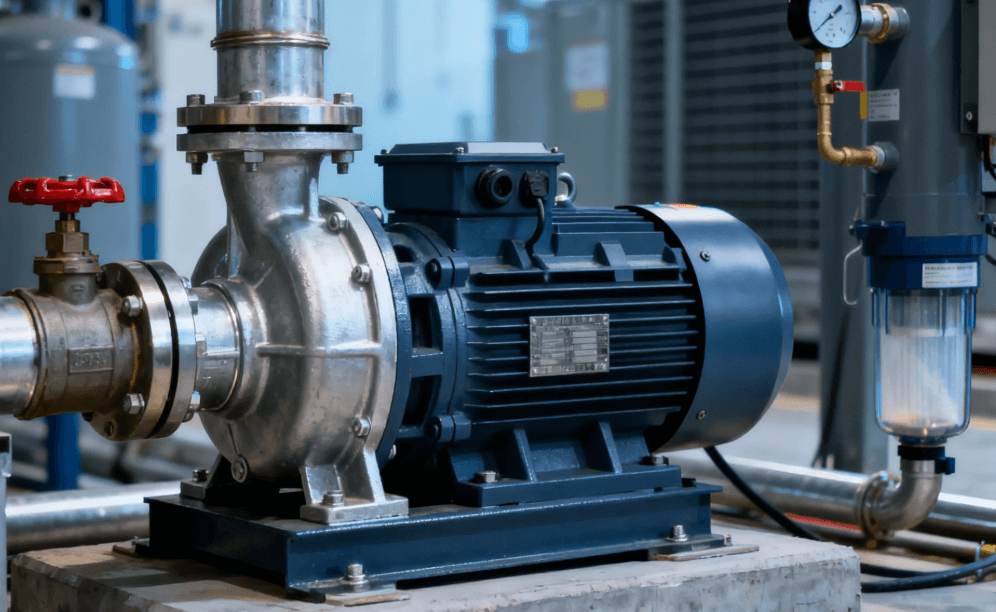

In the complex ecosystem of modern commercial and industrial HVAC (Heating, Ventilation, and Air Conditioning) systems, efficient fluid handling is not merely an operational detail but a direct determinant of overall energy consumption and climate control effectiveness. At the core of every chilled water loop, hot water distribution network, and condenser water circuit lies the Horizontal Centrifugal Pump. This machine is fundamentally responsible for moving large volumes of liquid against the resistance imposed by the piping, valves, and heat exchangers. Its design, characterized by a shaft mounted horizontally, offers ease of maintenance, robust stability, and unparalleled flexibility, making it the preferred choice over vertical or inline models for many medium-to-large-scale applications. Project engineers, facility managers, and procurement specialists must understand that the performance and reliability of the entire HVAC system hinge directly on the correct selection and operation of the Horizontal Centrifugal Pump. We will thoroughly examine the hydraulic principles, critical selection factors, and strategic deployment of this essential machinery to optimize energy efficiency and ensure long-term system integrity.

The Horizontal Centrifugal Pump operates on the principle of converting rotational kinetic energy into hydrostatic energy, creating the necessary pressure head to move fluid through a closed-loop system.

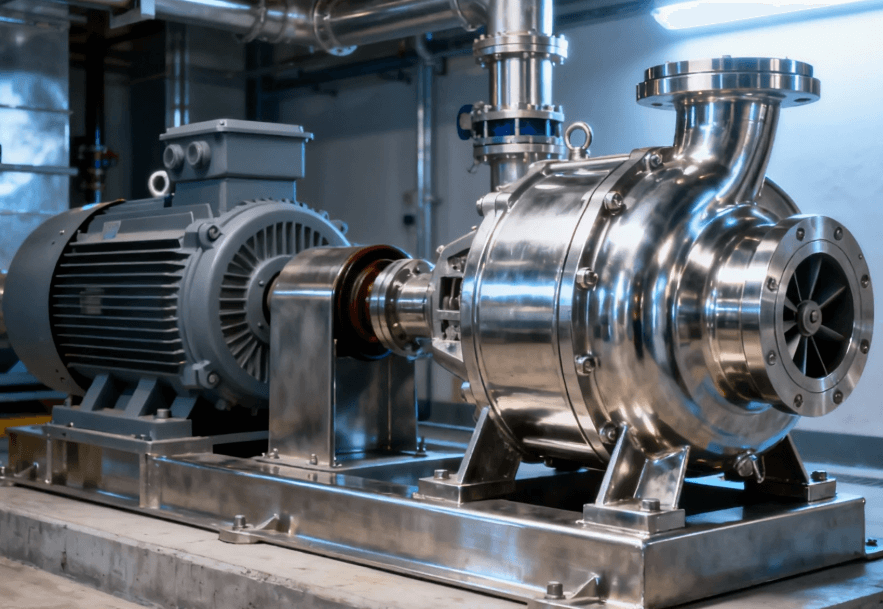

At the heart of the pump is the impeller, a rotating disc equipped with vanes. When the motor drives the impeller, the fluid drawn into the eye of the impeller is subjected to rapid rotation. This rotation accelerates the fluid outwards due to centrifugal force. As the fluid leaves the impeller tips at high velocity, it enters the volute—a spiral-shaped casing that gradually increases in area. This specific casing design serves a crucial purpose: it slows the velocity of the fluid and, in accordance with Bernoulli’s principle, converts that high kinetic energy into static pressure. This generated pressure, or "head," is what overcomes system friction and allows the fluid (like chilled or heated water) to reach all parts of the building. Because the shaft is horizontal, the pump's weight is optimally supported, minimizing vibration and maximizing the durability of the bearings and seals.

The typical construction of a Horizontal Centrifugal Pump features a casing split either along the shaft centerline (split case) or perpendicular to the shaft (end suction). For HVAC systems demanding high flow rates and easy maintenance, the horizontal split case design is often selected. This design allows the maintenance crew to access the internal components, such as the impeller and bearings, simply by removing the upper half of the casing, all without disturbing the heavy motor or the piping connections. This accessibility dramatically reduces downtime and simplifies crucial maintenance tasks, which translates directly into lower life-cycle costs for the entire HVAC installation.

Choosing the correct Horizontal Centrifugal Pump for a complex HVAC installation requires careful consideration of hydraulic needs, system resistance, and energy consumption metrics.

The most fundamental selection criterion involves matching the pump's performance curve—which plots flow rate (Q) against head (H)—to the system's resistance curve. The system curve represents the static and friction losses inherent in the piping network. The pump should be selected so that its operating point (where the two curves intersect) falls near the Best Efficiency Point (BEP) of the pump curve. Operating a Horizontal Centrifugal Pump far from its BEP leads to excessive vibration, premature seal and bearing failure, and dramatically reduced energy efficiency. Therefore, precise engineering calculation of the system head is a critical precursor to procurement.

In HVAC installations, particularly those involving roof-mounted cooling towers or specific boiler feed applications, the concept of Net Positive Suction Head (NPSH) is vital. NPSH is the pressure required at the pump's suction port to prevent cavitation—the formation and violent collapse of vapor bubbles within the fluid. Cavitation erodes the impeller and can quickly destroy the pump. The available NPSH (NPSHa) in the system must always exceed the required NPSH (NPSHr) specified by the manufacturer. Misunderstanding this parameter, especially in hot water systems where the fluid is close to its boiling point, can lead to severe operational issues and shortened pump lifespan.

Modern HVAC systems rarely run at a constant load. Chiller output, boiler demand, and building zones constantly fluctuate. Integrating a Variable Speed Drive (VSD) with the Horizontal Centrifugal Pump allows the motor speed to be adjusted dynamically to meet the actual instantaneous load requirement. By using VSDs, power consumption can be drastically reduced because of the Affinity Laws, which state that reducing the pump speed by half reduces the power consumption by a factor of eight. This technological integration is arguably the single most effective way to optimize the energy performance of the Horizontal Centrifugal Pump in a modern, automated HVAC environment.

The Horizontal Centrifugal Pump is widely deployed across key areas of HVAC infrastructure, requiring attention to material science and preventative maintenance for maximum longevity.

In central cooling systems, large Horizontal Centrifugal Pumps circulate chilled water from the chiller plant to Air Handling Units (AHUs) throughout the facility and simultaneously circulate condenser water to the cooling towers to reject heat. These pumps must be reliable, as a single failure can incapacitate the entire cooling system. The pump casing and impeller materials—often cast iron or bronze—are chosen for their durability and corrosion resistance against the treated water in these closed or semi-open loops. Given their critical role, deploying parallel pumps with automatic changeover capabilities is often an investment strategy utilized to ensure redundancy.

The longevity of a Horizontal Centrifugal Pump is inextricably linked to the quality of its installation. Precise shaft alignment between the pump and the motor is mandatory. Misalignment, even by a few thousandths of an inch, causes excessive radial and axial forces, leading to premature bearing failure, mechanical seal leakage, and high vibration levels. Although flexible couplings are used to accommodate minor deviations, they cannot compensate for poor initial alignment. Therefore, sophisticated laser alignment techniques must be applied during installation to ensure optimal performance and minimal wear over the pump's multi-decade lifespan.

Q1: Why is the Horizontal Centrifugal Pump often preferred over a vertical inline pump in large HVAC systems?

A: The Horizontal Centrifugal Pump is preferred for large systems due to its superior ease of maintenance (allowing access to internal parts without disturbing piping) and its robustness in handling large flow rates and the inherent stability provided by the horizontal shaft mounting.

Q2: What is the significance of the Best Efficiency Point (BEP) when selecting a Horizontal Centrifugal Pump?

A: The BEP is the operating point (flow rate and head) where the pump converts energy most efficiently. Operating the pump near its BEP minimizes energy waste, reduces vibration, and extends the lifespan of the seals and bearings.

Q3: How does a Variable Speed Drive (VSD) save energy on a Horizontal Centrifugal Pump?

A: A VSD saves energy by reducing the pump's rotational speed (RPM) when the system load is low. Due to the Affinity Laws, even a small reduction in speed results in a disproportionately large reduction in the electrical power consumed, leading to significant energy savings over time.

Subscribe for the latest news and insights

We respect your privacy

Connect on social media