The reliability and energy efficiency of any modern HVAC (Heating, Ventilation, and Air Conditioning) or domestic hot water system hinges critically on its water storage components, where the Stainless Steel Water Storage Tank has emerged as the definitive solution, setting the industry standard for durability, hygiene, and long-term performance. This material choice is increasingly crucial in comprehensive thermal systems where stored water is utilized for circulating heat, buffering energy, or providing sanitary potable supply, and is especially valued over traditional galvanized steel or lined tanks due to its superior resistance to corrosion and bio-fouling. For engineers, system integrators, and project managers in the HVAC sector, selecting this material represents a long-term investment decision that directly impacts compliance with health regulations, reduces maintenance costs, and sustains optimal system performance; therefore, understanding the specific properties that make the Stainless Steel Water Storage Tank the superior and most economically sound choice over the lifespan of a complex thermal system is essential for professional applications.

The foundational advantage of the Stainless Steel Water Storage Tank stems directly from the sophisticated metallurgical properties of stainless steel, which offer unparalleled resistance and resilience in dynamic, water-based environments.

The primary, non-negotiable benefit of stainless steel—typically specified as AISI 304 or 316 grade—is its exceptional, intrinsic resistance to corrosion. This resistance is achieved through the addition of chromium, which instantly forms a thin, stable, and self-repairing passive oxide layer on the steel's surface. Unlike carbon steel, which requires heavy lining or galvanization that inevitably degrades over time, stainless steel maintains its structural integrity and interior surface smoothness even when subjected to fluctuating water temperatures, high dissolved oxygen levels, and various chemical treatments. Consequently, the operational lifespan of a Stainless Steel Water Storage Tank significantly exceeds that of tanks made from less durable materials, directly translating into less frequent replacement and a demonstrably lower lifetime cost for complex HVAC and plumbing systems.

In any system involving the storage of potable water or domestic hot water, maintaining impeccable hygiene is paramount, and stainless steel delivers superior performance in this regard. It offers an inherently smooth, non-porous surface that actively resists the adherence of bacteria, the formation of biofilms, and the build-up of mineral scale deposits. This crucial hygienic property simplifies routine sanitation procedures and minimizes the risk of microbial colonization, such as Legionella, a significant public health concern often associated with porous or damaged tank linings. Furthermore, stainless steel is biologically inert, meaning it does not leach heavy metals or other contaminants into the stored water, ensuring the water quality remains completely pristine. This makes the Stainless Steel Water Storage Tank the material of choice for sensitive applications within the HVAC supply chain, including healthcare facilities, food processing plants, and high-end residential complexes.

The reliability and extreme versatility of the Stainless Steel Water Storage Tank establish it as an essential, high-performance component across several key disciplines within the integrated HVAC product ecosystem.

In large-scale commercial settings, such as hotels, hospitals, or multi-family residential towers, central DHW systems demand storage tanks capable of handling continuous, high-volume turnover and elevated temperatures while upholding stringent water quality standards. The Stainless Steel Water Storage Tank excels in this demanding environment because it safely withstands the significant thermal stress associated with high-temperature storage and repeated rapid reheating cycles. Additionally, its superior resistance to chloride corrosion—especially when using higher-grade 316 steel—is vital in coastal regions, hard water areas, or where aggressive chemical water treatment is necessary. This robust and consistent performance ensures that end-users receive reliable, safe, and clean hot water on demand, which is a non-negotiable pillar of modern building services.

In the context of modern, energy-efficient HVAC systems—particularly those utilizing high-efficiency heat pumps, solar thermal collectors, or Combined Heat and Power (CHP) units—buffer tanks play a fundamental role in balancing fluctuating energy production with actual demand. A well-designed buffer tank stores excess thermal energy, preventing the expensive short-cycling of the heat pump or boiler and dramatically improving overall system efficiency. When functioning as a thermal store, the Stainless Steel Water Storage Tank offers the necessary structural rigidity and compatibility with high-performance insulation, ensuring that stored thermal energy is retained with minimal loss over extended periods. This specific application is absolutely critical for optimizing the performance of renewables-integrated HVAC systems, directly reducing operating costs, and significantly increasing the longevity of the entire thermal plant.

Hydronic systems are the backbone of many large buildings, circulating water for effective cooling or heating through coils, fan units, and terminal equipment. Even in ostensibly closed-loop chilled water systems, corrosion can occur due to dissolved oxygen ingress or galvanic action between different metals. Utilizing a Stainless Steel Water Storage Tank for the expansion tank or system break tank provides a clean, chemically non-reactive environment for the system's vital water supply. This practice helps to maintain the purity and integrity of the circulating fluid, thereby protecting sensitive and expensive downstream components, such as high-efficiency pumps, automated control valves, and critical heat exchangers, from premature failure caused by rust or particulate contamination.

For one-stop HVAC suppliers and professional system installers, the distinct technical characteristics of the Stainless Steel Water Storage Tank translate into measurable benefits related to deployment, long-term operation, and simplified maintenance.

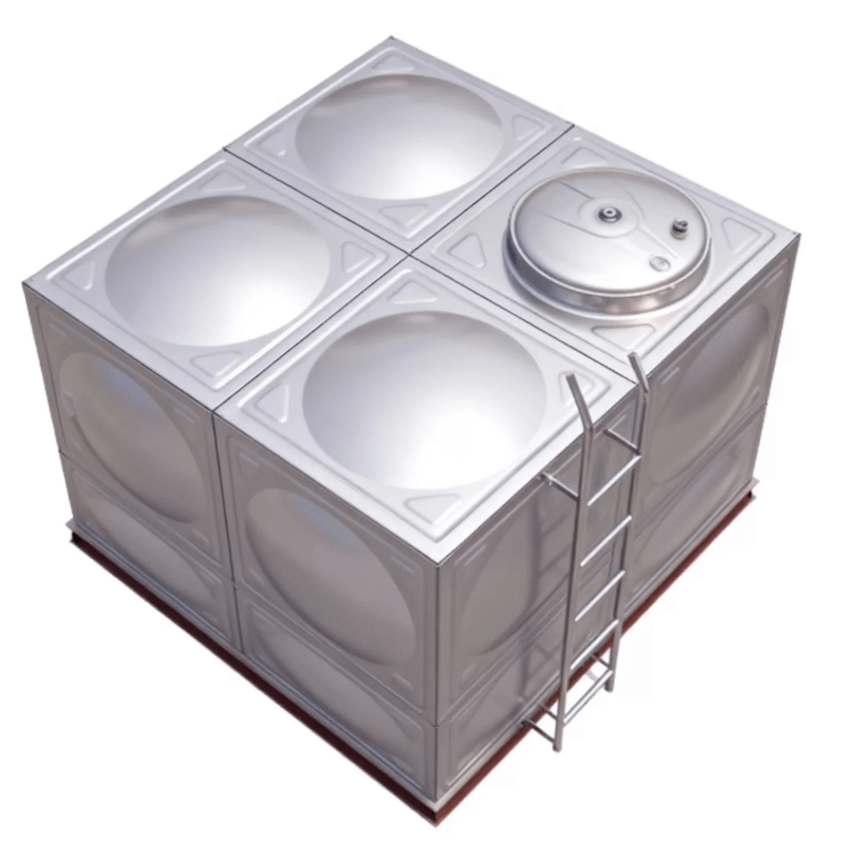

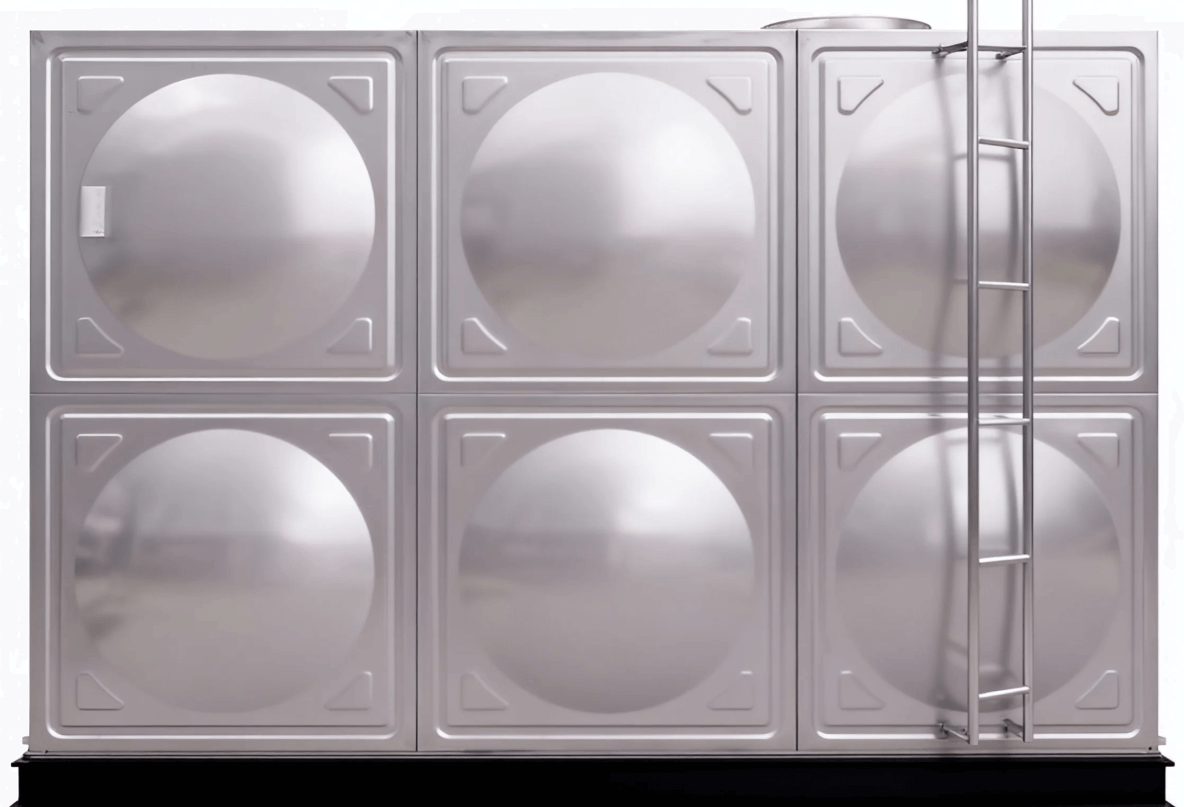

Stainless steel boasts a superior strength-to-weight ratio when compared to galvanized or lined carbon steel, enabling manufacturers to produce tanks with thinner walls that are structurally robust yet considerably lighter and easier to transport and lift into final position. Furthermore, the material's inherent strength provides greater flexibility in welding and connecting accessories; high-quality tanks feature precision-welded ports and specialized flanges that reliably accommodate various sensor probes, internal heat exchanger connections, and complex plumbing without compromising the structural integrity of the main vessel. This ease of reliable integration is vitally important for delivering highly customized and reliable HVAC solutions to clients.

Many high-specification Stainless Steel Water Storage Tanks are equipped with internal heat exchanger coils, frequently fabricated from stainless steel or sometimes copper, designed for exceptionally efficient heat transfer. These coils are commonly employed to transfer thermal energy generated by a boiler or a solar thermal array into the surrounding domestic hot water. The smooth, anti-scale surface characteristic of the stainless steel tank interior contributes significantly to sustained, high heat transfer efficiency by minimizing the build-up of mineral and oxide deposits which act as thermal insulators. This sustained efficiency is crucial for reliably meeting peak demand loads in demanding DHW applications and ensuring the primary heating source operates optimally without wasteful energy expenditure.

While the initial procurement cost for a high-grade Stainless Steel Water Storage Tank may be higher than that of a traditional lined carbon steel or plastic alternative, the total cost of ownership (TCO) is nearly always lower over a 20- to 30-year lifecycle. This massive cost reduction is directly achieved through several powerful factors: the complete elimination of periodic tank re-lining maintenance, the necessary reduction in chemical water treatment required to inhibit internal corrosion, and the virtual certainty of avoiding replacement costs associated with internal coating failure. Ultimately, system owners benefit significantly from fewer service interruptions and substantially reduced labor expenses over the tank's extensive operational lifetime, confirming stainless steel as the most economically prudent and sustainable choice for professional, high-performance HVAC systems.

Q1: Which type of stainless steel is typically used for a Stainless Steel Water Storage Tank in demanding HVAC environments?

A: While AISI Grade 304 is suitable for many standard applications, Grade 316 stainless steel is usually specified for the most demanding environments, particularly those involving high temperatures, hard water, or water with elevated chloride content, due to its enhanced resistance to pitting corrosion.

Q2: How does the Stainless Steel Water Storage Tank contribute to overall system energy efficiency?

A: Stainless steel tanks contribute by ensuring high efficiency in two main ways: (1) Their surface resistance to scaling keeps internal heat exchanger coils operating at optimal thermal transfer rates, and (2) Their robust structure allows for maximum external insulation thickness, minimizing thermal energy loss to the environment.

Q3: Is a Stainless Steel Water Storage Tank suitable for both high-temperature and low-temperature fluid storage?

A: Yes. Stainless steel is inherently resistant to thermal shock and maintains its structural and anti-corrosive properties across a wide operational temperature range, making it equally suitable for storing high-temperature domestic hot water and low-temperature chilled water used in air conditioning and process cooling systems.

Subscribe for the latest news and insights

We respect your privacy

Connect on social media