The efficiency and comfort of modern commercial buildings are fundamentally tied to the sophistication of their heating, ventilation, and air conditioning (HVAC) infrastructure. Among the myriad of technologies driving this sector forward, the Variable Air Volume (VAV) system stands out as a paramount solution. Unlike older, constant-volume systems which maintain temperature by reheating or dumping excess cooled air, VAV technology operates on a far more nuanced principle: delivering only the precise amount of conditioned air required to meet a space's current thermal load. This precise control not only ensures optimal user comfort but also yields substantial energy savings, making it an indispensable component in the pursuit of sustainable building operations.

As a user or integrator of one-stop HVAC solutions, understanding the mechanics, benefits, and applications of the Variable Air Volume system is crucial for making informed decisions that impact both operational costs and environmental footprint. This in-depth guide is designed to provide you with a comprehensive, professional understanding of this essential technology.

At its heart, the Variable Air Volume system is a sophisticated method of air distribution. Instead of constantly running the central air handler at maximum capacity, the VAV system dynamically adjusts the volume of supply air based on the real-time heating and cooling needs of individual zones or rooms within a building.

To appreciate the value of VAV, a brief comparison with the traditional Constant Air Volume (CAV) system is illuminating. CAV systems provide a steady, fixed flow of air into a space. When less cooling is needed, a CAV system often relies on inefficient methods, such as reheating the cooled air or bypassing it, which is inherently wasteful. In sharp contrast, the Variable Air Volume system utilizes variable frequency drives (VFDs) on the supply and return fans. These VFDs allow the fan speed, and thus the airflow rate, to be precisely modulated. When the thermostat in a zone signals that the setpoint has been reached, the corresponding VAV terminal unit (or VAV box) reduces the airflow. This reduced demand cascades back to the central air handler, which then slows its fans, dramatically cutting energy consumption, particularly in part-load conditions which constitute the majority of operating hours.

A typical Variable Air Volume system comprises several integrated components working in concert:

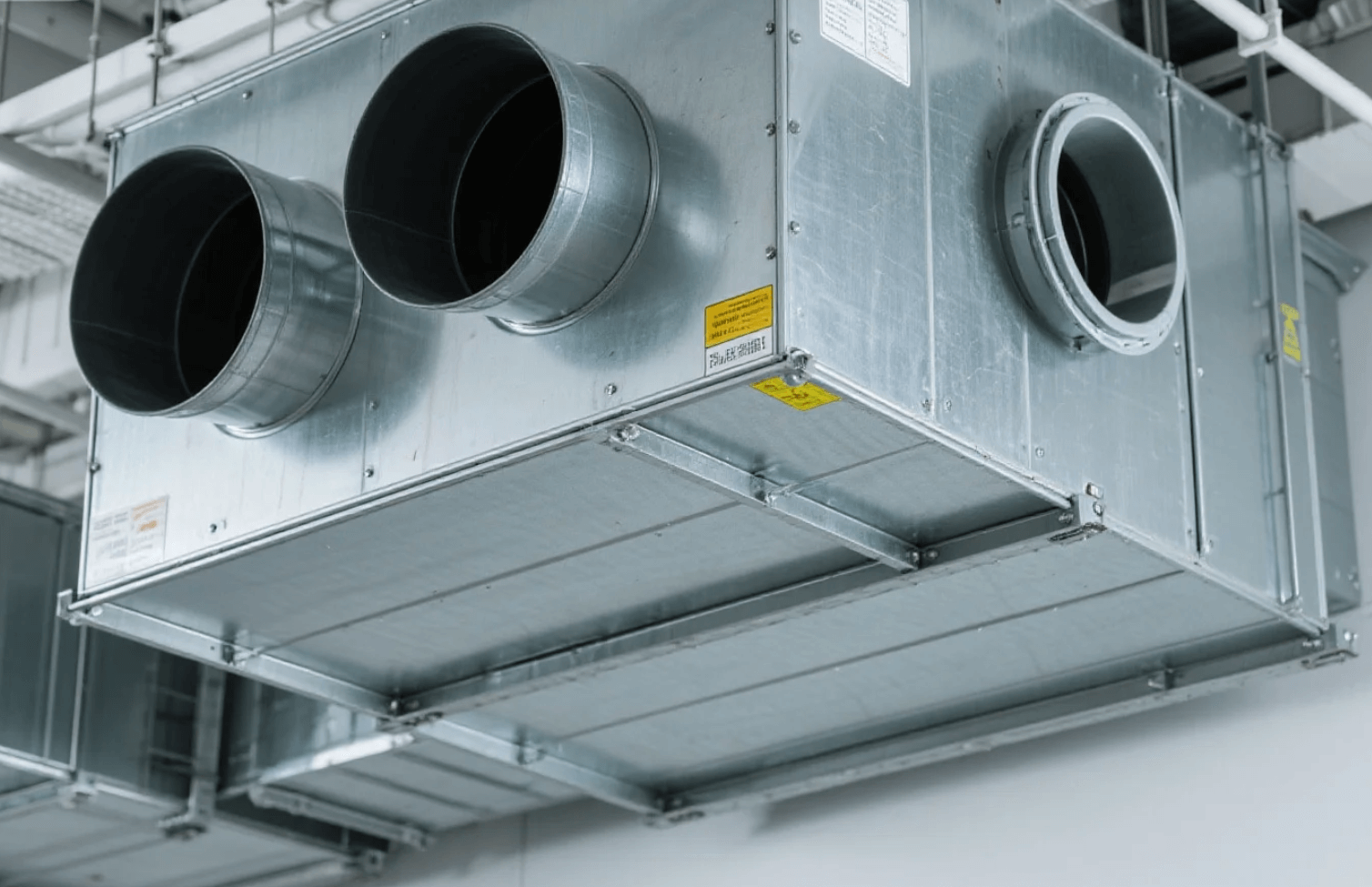

Central Air Handling Unit (AHU): This unit filters, heats, or cools the air before sending it into the ductwork. It features VFD-driven fans.

Main Ductwork: Carries the conditioned air from the AHU throughout the building.

VAV Terminal Units (VAV Boxes): These are strategically placed in each thermal zone. They contain a damper that opens or closes to regulate the volume of air entering the zone, and often include a reheat coil (electric or hot water) for fine-tuning the temperature.

Thermostats and Sensors: Placed in each zone, these devices monitor the current temperature and communicate the demand signal back to the VAV box and the central building management system (BMS).

In the realm of one-stop HVAC product integration—where systems are designed for seamless installation and operational efficiency—the Variable Air Volume system offers unparalleled advantages. The modular nature of VAV boxes allows integrators to tailor airflow and temperature control to highly specific zone requirements, a flexibility not easily achieved with other system types.

Energy efficiency is arguably the most significant selling point of the Variable Air Volume system. Since fan power consumption is proportional to the cube of the fan speed, a small reduction in fan speed results in a disproportionately large reduction in energy use. When a VAV system slows its fans to 80% of full speed, for example, the energy consumption drops to approximately (0.8)3, or 51.2% of the original power required. Over a year, this continuous modulation in large commercial offices, educational facilities, or healthcare settings translates into substantial reductions in utility bills, directly addressing one of the major operational costs for building owners.

Beyond energy statistics, the VAV system excels at maintaining a comfortable environment. Each zone's VAV box operates independently, ensuring that temperature fluctuations are minimized, irrespective of changing solar loads, occupancy levels, or equipment heat gains in adjacent spaces. Furthermore, contemporary VAV systems can be designed to maintain minimum ventilation rates for optimal Indoor Air Quality (IAQ) even when cooling demand is low. By providing the exact quantity of air needed, issues related to over-cooling or stratification are effectively mitigated, leading to fewer occupant complaints and higher productivity.

The successful implementation of a Variable Air Volume system requires careful design and calibration, particularly when integrated into a sophisticated one-stop HVAC product suite.

A key design aspect is the control of static pressure within the ductwork. As VAV boxes modulate their dampers, the pressure in the main duct changes. The AHU fan’s VFD must be controlled by a static pressure sensor located in a strategic, often remote, point in the ductwork. This arrangement ensures that sufficient—but not excessive—pressure is maintained throughout the system to deliver air to all zones, preventing unnecessary noise and fan energy wastage.

While energy savings are maximized by reducing air volume, there is a minimum airflow required to maintain adequate ventilation and prevent discomfort. This minimum flow is known as the system "turndown." When a zone requires heating in a system designed primarily for cooling (common in perimeter offices during mild weather), the VAV box may utilize a reheat coil. While this uses additional energy, it is often necessary for precision temperature control, and its consumption is typically offset by the larger savings achieved through fan power reduction across the rest of the Variable Air Volume system. Proper system sequencing is utilized to minimize the need for simultaneous cooling and reheating.

The Variable Air Volume system is no longer just an option; it is a prerequisite for high-performance, sustainable commercial HVAC applications. Its ability to decouple the supply of conditioned air from the central plant's full capacity allows for profound energy savings and delivers a level of zone-specific control unmatched by constant-volume alternatives. For users and providers of one-stop HVAC solutions, embracing VAV technology is a clear step towards creating smarter, greener, and more comfortable built environments. Its integration represents a forward-thinking investment that pays dividends through reduced operational expenditure and enhanced occupant satisfaction.

Q1: Is a Variable Air Volume system suitable for small commercial buildings?A: While historically applied to large buildings, smaller, modular VAV systems are becoming increasingly common and viable for medium-sized commercial spaces, especially where precise zone control and energy efficiency are priorities.

Q2: How is VAV system maintenance different from other HVAC systems?A: VAV systems require routine maintenance similar to other central air systems, but technicians must also focus on the calibration and functionality of the VAV boxes, dampers, and the VFDs on the air handler fans to ensure accurate airflow modulation.

Q3: What is the typical lifespan of a VAV system?A: With proper design and maintenance, the central air handling components of a VAV system can last 15-20 years, while VAV terminal units often have a similar lifespan, though controls and sensors may require updates sooner.

Q4: Can a VAV system also handle outside air for ventilation?A: Absolutely. A central air handler integrated with a Variable Air Volume system is designed to condition and distribute the required volume of outdoor air, which is essential for meeting ventilation codes and maintaining high Indoor Air Quality (IAQ).

Subscribe for the latest news and insights

We respect your privacy

Connect on social media